The fifth article is about the drain valve.

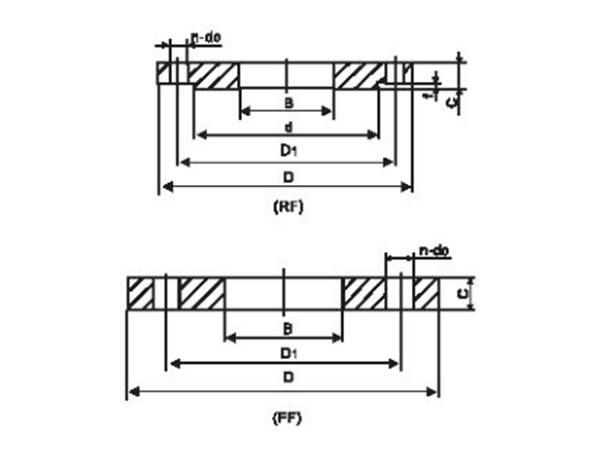

2025-04-13 12:00:06Flange joint is an indispensable connecting component in industrial pipeline system, which is widely used in petroleum, chemical industry, electric power, water treatment and other fields. It firmly connects two pipes, pipe fittings or equipment together through bolts and sealing gaskets to ensure the safety and stability of fluid transmission. The main function of the flange joint is to achieve a reliable connection of the pipeline system, while facilitating disassembly and maintenance.

According to the structural form, flange joints can be divided into flat welding flange, welding flange, socket welding flange, loose flange and other types. Each type is suitable for different working conditions. For example, flat welding flange is simple to manufacture, low cost, suitable for low pressure environment; welding flange high strength, high pressure, suitable for high temperature and high pressure occasions. In terms of materials, flange joints are usually made of carbon steel, stainless steel, alloy steel, etc. to meet the requirements of different media and working conditions.

The design and selection of flange joints should consider the pressure level, temperature range, medium characteristics and sealing performance. Standard codes such as ANSI, ASME, GB, DIN, etc. provide detailed dimensional and technical requirements for flanged joints to ensure their worldwide interchangeability and compatibility.

In practical applications, the installation quality of flange joints directly affects the operational reliability of the system. The correct installation steps include checking the flatness of the flange surface, selecting the appropriate gasket material, and tightening the bolts evenly. In addition, regular maintenance and testing are also the key to extending the service life of flange joints.

In short, as the core component of the pipeline system, the flange joint occupies an important position in modern industry with its excellent connection performance and wide adaptability. With the advancement of technology, the application of new materials and design methods will further improve the performance of flange joints and promote the sustainable development of related industries.

.png)