The fourth article about the check valve

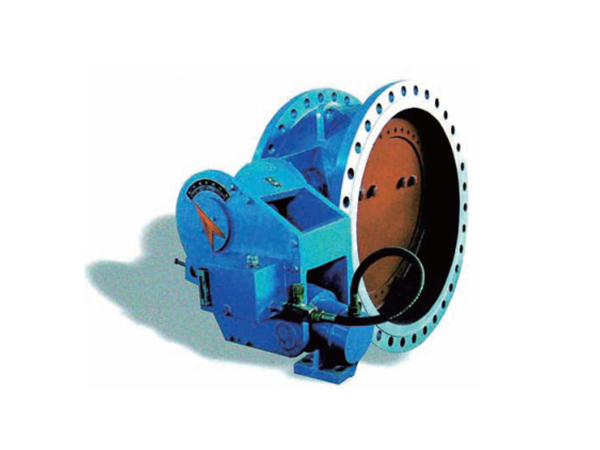

2025-04-13 11:43:31The check valve is an automatic valve used to prevent the reverse flow of fluid in the pipeline system. It is widely used in water supply, drainage, petroleum, chemical, pharmaceutical and other fields. According to the different structure, the check valve can be divided into lift, swing and butterfly type. The lift check valve is suitable for small diameter pipes with good sealing performance; the swing check valve is suitable for large diameter pipes with low resistance; the butterfly check valve is small in size and easy to install. The working principle of the check valve is to use the pressure difference of the fluid to realize the automatic opening and closing. When the fluid is flowing forward, the pressure overcomes the spring or gravity to push the valve flap to open; when the fluid stops or flows backward, the pressure difference closes the valve flap, thus preventing the reverse flow from occurring. This feature ensures the safety and stability of the system, such as preventing water hammer when the water pump is stopped, or avoiding medium mixing in gas transportation. Select the appropriate check valve to consider the working conditions, such as working pressure, temperature, medium properties and pipe size. In terms of materials, cast iron, stainless steel, bronze, etc. have their own advantages and should be selected according to actual needs. In addition, regular maintenance and inspection is also an important part of ensuring the normal operation of the check valve, including cleaning impurities in the valve body, checking the wear of the sealing surface and replacing damaged parts. In short, as a key component in the pipeline system, the check valve plays an important role in ensuring the one-way flow of fluid. Proper selection, installation and maintenance can extend its service life and improve the reliability of the overall system.

.png)