留言

客服电话

0371-68197888

电子邮件

zzzf666666@163.com

微信

Valve Solutions for the Oil Industry

Typical Application Scenarios

In the chemical industry, valves are core equipment for process control, safety isolation, and medium management, and they are used throughout almost all production processes. Below is a detailed classification of the main systems in the chemical industry and the types of valves required:

-

Oil and Gas Exploration and Production System

Wellhead Equipment (Christmas Tree)

Fracturing and Water Injection Systems

-

-

Oil and Gas Transmission System

Mainline Block Valves

Station Systems

-

-

Refining and Petrochemical System

Atmospheric and Vacuum Distillation Units

Catalytic Cracking Units

Hydrotreating Units

-

-

Storage, Transportation, and Terminal System

Tank Farms

LNG Receiving Terminals

-

-

Auxiliary and Safety Systems

Fire Protection Systems

Blowdown and Drainage

-

Improper valve selection can lead to major accidents such as leaks and explosions (e.g., uncontrolled well blowouts). Therefore, it is not only necessary to strictly adhere to industry standards (such as API 6D and ASME B16.34) but also to ensure absolute control over product quality.

Gate Valve/Slab Valve

Safety Valve

High-Pressure Ball Valve

Check Valve

Fully Welded Ball Valve

Pressure Reducing Valve

Control Valve

Pigging Valve

High-Temperature Gate Valve

Abrasion-Resistant Slide Valve

High-Pressure Globe Valve

Breather Valve

Emergency Shut-Off Valve

Ultra-Low Temperature Ball Valve

Firefighting Foam Valve

Relief Valve

Products

Zheng Valve Machinery is capable of providing you with comprehensive, professional, and reliable valve products to meet the needs of your engineering projects.

- Butterfly valve

- Gate valve

- Ball valve

- Check Valve

- Cone valve

- Flow and pressure regulating valve

- Exhaust valve

- Control Valve

- Retractor

pipe network regulating valve

Multifunctional piston is a new type of valve, with a variety of adjustment and control functions. The main functions are: water level control, decompression, check, pressure relief, flow control, and drainage at the bottom of the dam. The maximum inlet and outlet pressure difference can reach 40 kg/cm. Especially in the large diameter, high pressure and large pressure conditions show its superior adjustment and control function.

ZF Cone Valve (Energy-dissipation Valve)

Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted conical plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve. Cone valve in addition to the end of the channel is provided with a conical valve core, all the moving parts are set in the valve flow channel outside, so that the valve body internal flow is usually smooth, large flow and pressure drop loss is small, the entire working range will not produce cavitation and vibration, and in the small flow still has good flow control effect. The conical valve developed by our company has a fixed inverted conical structure. It is supported by hydraulic design and four guide wing blades used to reduce vibration. The flow rate is controlled by the front and back movement of the external movable casing. The valve body is respectively provided with metal-to-metal valve seats and supplementary soft sealing valve seats, which constitute a composite valve seat to ensure sealing performance. When discharged into the atmosphere, the water flow spreads at a wide cone angle and breaks down into a thin spray pattern, expending energy in the air. Usually according to the actual needs, can be required to control the water flow area, then install a different form of deflector at the outlet, which can not only mix the air with sufficient water, but also concentrate the flow. The results of the cone valve test showed no significant vibration, and the discharge coefficient was around 0.9 with or without the shroud when the fixed cone was fully open. ZF cone valve is mainly used in hydropower stations, reservoirs and urban water supply and drainage areas.

ZF Cone Valve (Energy-dissipation Valve)

Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted cone plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve.

Double eccentric flanged butterfly valve

.png)

Double eccentric butterfly valve adopts double eccentric structure as a whole, two-way sealing performance is more stable, access to national patent (patent number ZL 02284270.5), is the old pipeline transformation, maintenance and supporting soft sealing valve of choice.

PQ347H eccentric half ball valve

Eccentric hemispherical valve is a new type of industrial valve developed by our company on the basis of introducing and absorbing foreign such valve structure. It can be widely used in medium pressure pipelines such as petroleum, chemical industry, metallurgy, electric power, water supply, etc., and is especially suitable for use in fluid medium pipelines containing impurities and particles.

H44X rubber flap check valve

H44 x (SFCV) series of rubber flap check valve parts design is mainly composed of valve body, valve cover and rubber flap three main parts. The rubber flap in the valve is made of steel plate and steel. The service life of the switch can reach 1 0 0 times. H44X(SFCV) series rubber flap check valve adopts full flow area design, with small head loss, not easy to accumulate debris, easy maintenance and other characteristics. The H44(SFCV) series rubber flap check valve produced by our company is mainly applicable to the water supply and drainage system with dry horizontal installation and can be installed at the water outlet of the water pump to prevent back flow and water hammer damage to the pump. The valve can also be installed on the bypass pipe of the water inlet and outlet pipes of the reservoir to prevent the backflow of the pool water into the water supply system.

HH49X Micro-resistance Slow-closing Acoustic Butterfly Check Valve

HH49X series micro-resistance slow closing muffler butterfly check valve is the latest product developed by our company. It integrates the various advantages of many similar products, and is introduced to the market with its unique design, and is quickly praised by the majority of users.

Eccentric three-stage slow-closing check valve

The eccentric three-stage slow-closing non-return butterfly valve is a new type of check valve developed by our company on the basis of butterfly valve and the same type of check valve, which can realize three-stage closing, and has obtained a national patent (its patent number: ZL200520143544.X)

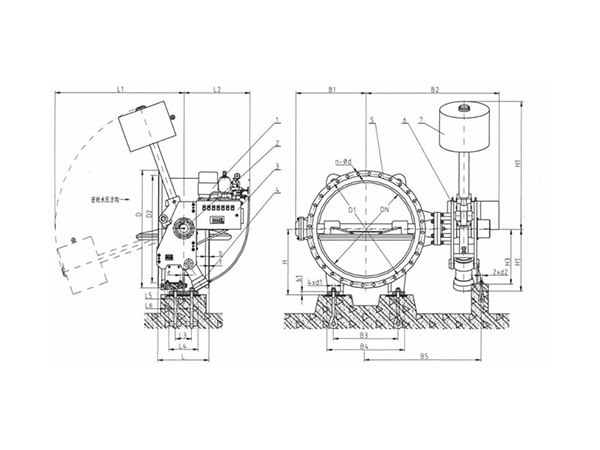

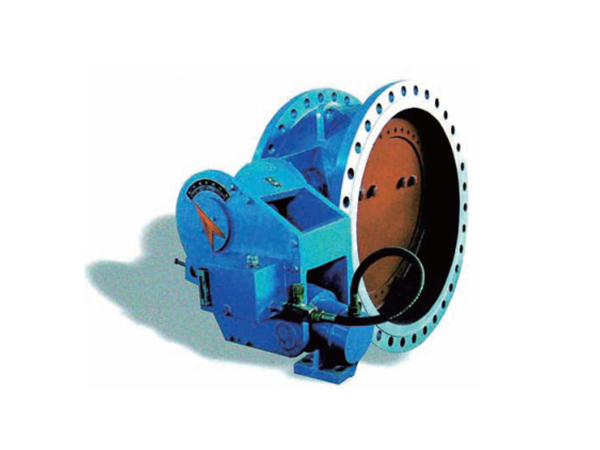

Heavy hammer type automatic pressure holding hydraulic control slow closing non-return butterfly valve

Hydraulic control slow closing butterfly valve is currently our company's more advanced pipeline control equipment, mainly installed in the hydropower station turbine inlet, used as turbine inlet valve; or installed in water conservancy, electricity, water supply and drainage and other types of pumping station pump outlet. Replace the function of check valve and gate valve. When working, the valve and the pipeline host are equipped with the platform. According to the principle of hydraulic transition process, through the preset opening and closing procedure, the water hammer in the pipeline is effectively removed, the reliable cut-off of the pipeline is realized, and the safety of the pipeline system is protected.

Eccentric three-stage slow-closing non-return butterfly valve

Overview: Eccentric three-stage slow-closing non-return butterfly valve is a new type of check valve developed by our company on the basis of butterfly valve and the same type of check valve, which can realize three-stage closing. Performance characteristics: 1. The structure is simple and the non-return effect is good. 2. The slow closing system is less affected by the medium in the pipeline, and the adjustment and maintenance are simple.

BF single flange loose sleeve limit expansion joint

BF type single flange loose sleeve limit expansion joint is a pipe connection device composed of loose sleeve expansion joint and a limit short pipe. Its main function is to prevent leakage or damage of the compensation joint due to excessive displacement of the pipeline, and to absorb axial displacement and bear axial pressure thrust within the allowable displacement range.

B2F double flange type limit expansion joint

Double flange limit expansion joint is composed of body, sealing ring, gland, telescopic short tube and other major components. On the basis of the original performance of the loose sleeve expansion joint, a limiting device is added, and the maximum expansion amount is locked with a double nut. The pipeline can freely expand and contract in the allowable expansion amount. Once it exceeds its maximum expansion amount, it will be limited to ensure the safe operation of the pipeline. It is especially suitable for the connection in the pipeline with vibration or certain inclination and turning.

XTQ1 RF Flexible Rubber Joint

XTQ1 RF flexible rubber joint is a flexible coupling used in piping systems. It is mainly composed of a rubber sphere composed of an inner rubber layer, a nylon cord fabric reinforcement layer and an outer rubber layer, and a loose metal flange. It has the characteristics of high pressure resistance, good elasticity, large displacement, balanced pipeline deviation, absorption of vibration, and noise reduction. It is widely used in water supply and drainage, circulating water, HVAC, fire protection, papermaking, pharmaceuticals, petrochemicals, ships, water pumps, Piping systems such as compressors and fans

CC2F detachable double flange loose sleeve force transmission compensation joint

CC2F type detachable double flange loose sleeve force transmission compensation joint is a joint with flange short pipe and force transmission screw on the basis of flange loose sleeve compensation joint. Its main function is to transmit the pressure thrust (blind plate force) of the connecting piece and compensate for the pipeline error. At the same time, it has a certain amount of adjustment to facilitate the adjustment of the construction environment.

CF single flange force transmission joint

The CF type single flange loose sleeve force transmission joint is an important connector used in the pipeline system, mainly used for the loose sleeve connection of pumps, valves and pipelines and other equipment. It consists of a loose sleeve expansion joint, a short pipe flange and a force transmission screw. It adopts a trapezoidal rubber sealing ring, is fastened by gland bolts, and uses rubber compression elastic deformation to achieve static sealing, effectively preventing medium leakage

CARX compound exhaust valve

This series of composite exhaust valve is suitable for installation in the pump outlet or water distribution pipeline. It is used to eliminate a large amount of air gathered in the pipeline, or the trace air gathered at the higher part of the pipeline is discharged into the atmosphere to improve the use efficiency of the pipeline and the water pump, and once the negative pressure is generated in the pipe, the valve quickly sucks in the outside air to protect the pipeline from damage caused by negative pressure.

SCAR sewage compound exhaust valve

Overview The product is used at the highest point on the sewage pipe or where there is closed air to remove the gas in the sewage pipe to dredge the pipe. Make the pipeline run normally. If the valve is not installed, the pipeline will be closed, so that the sewage flow rate will reach the air resistance and even be interrupted. Working principle When the sewage in the pipe moves, the valve flap stops at the lower part of the fixed door frame. When the air is exhausted, the sewage enters the valve to float the ball 50 first, and then passes it to the valve until it is closed. The naturally occurring gas in the tube will be concentrated to the upper part of the tube to a considerable extent, and the valve hole will be discharged. Performance characteristics The principle of SCAR exhaust valve is the same as that of CARx exhaust valve, except that the structure is slightly changed and the lever mechanism is slightly improved (as shown in the figure). This controls the float ball at the lower part, so that dirt can only wrap around the upper exhaust port at the lower part of the valve body without affecting the sealing performance. This product is dedicated to the exhaust valve of the sewage pipeline project.

SCAR sewage compound exhaust valve

Product overview: This product is used for the highest point on the sewage pipe or a place with closed air to exclude the gas in the sewage pipe to dredge the pipe. Make the pipeline run normally, if not installed this valve, the pipeline will appear closed air, so that the flow rate of sewage by air resistance, and even interrupted. Working principle: when the sewage in the pipe moves, the valve flap stops at the lower part of the fixed door frame. When the air is exhausted, the sewage enters the valve to float the ball first and pass it to the valve until it is closed. The naturally occurring gas inside the tube will be concentrated to the upper part of the tube to a considerable extent, and the valve hole will be discharged.

CARX compound exhaust valve

CARx Composite Exhaust Valve The valve body is barrel-shaped, and the internal parts of the valve include stainless steel float ball, lever and disc. The valve is installed at the outlet of the pump or in the water distribution pipeline to exclude the air in the pipe to improve the efficiency of the pipeline and the water pump. When negative pressure is generated inside the tube-once. This valve quickly sucks in outside air to prevent damage to the pipeline due to negative pressure. Composite exhaust valve for the highest point on the pipeline or a closed place, the gas in the tube to clear the pipeline, to achieve normal work. If the exhaust valve is not installed, the liquid flowing in the pipe will generate dynamic heat and cause gas to form a short circuit, which will make the water outlet capacity of the pipe fail to meet the requirements. Secondly, the pipe will have negative pressure when the pipe is running and the pump will stop, which will cause the pipe to vibrate or rupture. The exhaust (suction) valve quickly sucks air into the pipe to prevent pipe vibration or rupture. Its working principle is: When the water injection in the pipe starts, the valve flap is in the open position to perform a large amount of exhaust. When the air is exhausted, the valve is filled with water, the float rises and drives the valve flap to close, and the exhaust is stopped. When the water in the pipe is transported normally. If a small amount of air collects in the valve to a considerable extent, the water level in the valve drops, and the air is discharged from the small hole. When the water pump stops, the water in the pipe is empty or negative pressure is generated in the pipe. At this time, the plug head is quickly opened to inhale air to ensure the safety of the pipeline. Medium temperature: 0-80 ℃.

YX741X adjustable pressure regulator valve

The adjustable pressure relief valve is a special valve installed on the water supply and drainage system pipeline of high-rise buildings to reduce the inlet pressure to a certain outlet pressure. The valve relies on its own energy to keep the outlet pressure stable at the set value, that is, the outlet pressure does not change due to the change of inlet pressure and flow rate. A self-cleaning filter screen is installed at the inlet of the valve control system to make the specific gravity larger by using fluid characteristics, larger diameter suspended particles will not enter the control system, to ensure that the system circulation unimpeded, so that the valve can operate safely and reliably. The system is sensitive and has a long service life.

AX742X Safety Pressure Relief Holding Valve

Installed in high-rise buildings, fire water supply systems and other water supply systems on the pipeline, when the pressure in the water supply pipeline exceeds the set pressure of the pressure relief valve, the pressure relief valve automatically opens for rapid pressure relief to protect the safety of the pipeline, and can also be used as a holding valve to ensure the water supply pressure upstream of the main valve. Can accurately maintain the same security set pressure, one and overpressure, pressure relief valve quickly open, timely pressure relief. Close smooth and reliable, eliminate the pressure after-wave.

200X pressure reducing valve

200X pressure reducing valve is an intelligent valve that uses the energy of the medium itself to adjust and control the pipeline pressure. 200X pressure reducing valve is used for domestic water supply, fire water supply and other industrial water supply systems. By adjusting the decompression pilot valve, the outlet pressure of the main valve can be adjusted. The outlet pressure does not change due to changes in inlet pressure and inlet flow. The outlet pressure is safely and reliably maintained at the set value, and the set value can be adjusted as needed to achieve the purpose of decompression. The valve has accurate decompression, stable performance, safety and reliability, convenient installation and adjustment, and long service life.

500X Pressure Relief Valve

500X pressure relief/holding valve is composed of main valve, pilot valve, needle valve, ball valve, micro filter and pressure gauge, hydraulic control pipe system. The use of hydraulic automatic operation, that can be used as a pressure relief valve can also be used as a holding valve. When the pressure relief valve is used, it can maintain the pressure of the water supply circuit below the set safety value and maintain the upstream water supply pressure of the main valve o. Its working principle, when the pilot valve is adjusted to the pressure relief state, the water flows to the outlet through the needle valve, the main valve control room, ball valve A, pilot valve and ball valve B, and the main valve is open at this time. When the inlet pressure exceeds the safety value set by the pilot valve, the pressure relief pilot valve will automatically open, and part of the water will be released through the ball valve c to relieve the pressure of the pipeline.

JM744X / JM644X quick-opening mud discharge valve

JM744X,JM644 diaphragm type hydraulic, pneumatic quick-opening mud valve, is a kind of hydraulic source or pneumatic source actuator angle type cut-off valve. It is usually installed in rows on the outer wall of the bottom of the sedimentation tank to remove the sediment and dirt from the bottom of the tank. The valve is divided into two chambers by nylon reinforced rubber diaphragm, which is connected to hydraulic or pneumatic source, and controlled by electric or manual two-position four-way reversing valve to realize rapid mud discharge. The valve will replace the piston diaphragm, no movement friction, more suitable for mud and other granular media. Greatly improve the service life of the valve.

JM744X / JM644X hydraulic and pneumatic angle type quick opening mud valve

JM744X hydraulic and pneumatic JM644x diaphragm type quick-opening mud valve adopts double-chamber diaphragm transmission mechanism instead of piston type mechanism, which has no movement wear and long service life. The inside of the diaphragm is made of folded composite material. Greatly improves the elongation of the diaphragm and prolongs the service life of the diaphragm during the opening and closing of the valve. Not easily broken. And can withstand higher pressure. Stay with electric two-position four-way valve or manual two-position four-way or to the valve centralized control, easy to operate, flexible valve opening and closing. This valve is mainly installed outside the bottom wall of the sedimentation tank to exclude the sediment and dirt at the bottom of the tank.

JD745X multi-function water control valve

Multi-function water control valve is installed in the high-rise building water supply system and other water supply system of the pump outlet, to prevent the media back, water hammer and water hammer phenomenon of intelligent valve. The valve has three functions of electric valve, check valve and water hammer eliminator, which can effectively improve the safety and reliability of water supply system. The technical principle of stage opening, quick closing and slow closing to eliminate water hammer is integrated. To prevent the generation of pump water hammer and stop pump water hammer. Just operate the pump motor opening and closing button, the valve can be automatically opened and closed according to the pump operating procedures, with large flow and small pressure loss. Suitable for valves below 600 caliber.

Remote water meter

Wireless remote transmission intelligent water meter is installed in the water meter wireless remote transmission module, through pulse/photoelectric sampling, is a wireless automatic meter reading system in the electromechanical conversion of zero error intelligent remote transmission water meter. Wireless remote water meter adopts LoRa modulation technology to send and receive data wirelessly, which has the characteristics of ultra-low power consumption, strong performance and long transmission distance. At the same time, it has high anti-interference and high reliability. It greatly surpasses the existing GFSK modulation module in stability, anti-interference ability and receiving sensitivity. It solves the problem that the traditional design scheme can not take into account the long-distance transmission, anti-interference and low power consumption at the same time, and becomes the choice of wireless applications with long-distance transmission and high reliability requirements. Meter can realize automatic maintenance, do not need construction wiring, do not need professional maintenance, easy to install and use

Remote Water Meter-Test

Wireless remote transmission intelligent water meter is installed in the water meter wireless remote transmission module, through pulse/photoelectric sampling, is a wireless automatic meter reading system in the electromechanical conversion of zero error intelligent remote transmission water meter. Wireless remote water meter adopts LoRa modulation technology to send and receive data wirelessly, which has the characteristics of ultra-low power consumption, strong performance and long transmission distance. At the same time, it has high anti-interference and high reliability. It greatly surpasses the existing GFSK modulation module in stability, anti-interference ability and receiving sensitivity. It solves the problem that the traditional design scheme can not take into account the long-distance transmission, anti-interference and low power consumption at the same time, and becomes the choice of wireless applications with long-distance transmission and high reliability requirements. Meter can realize automatic maintenance, do not need construction wiring, do not need professional maintenance, easy to install and use

GJQ(X)- DF Single Sphere Flexible Rubber Joint

GJQ(X)-DF single-sphere flexible rubber joint diameter, length and displacement parameter table-description: ① please indicate the structural length and connection size of the standard when ordering. ② If the relevant parameters of the flexible rubber joint are not within the scope of the above table, please indicate that the company can design and manufacture on its behalf.

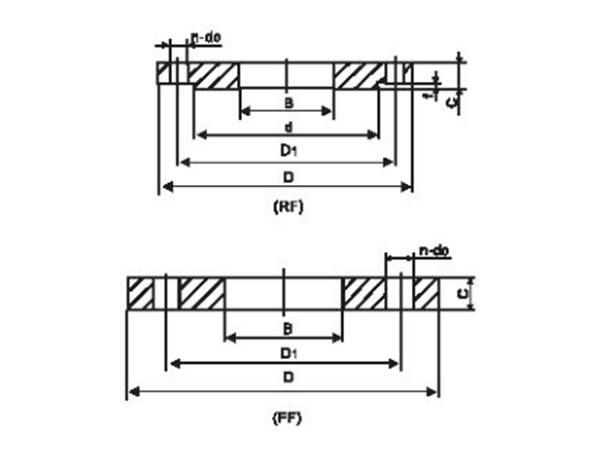

Convex (flat) panel type flat welded steel pipe flange

Convex (flat) plate flat welded steel pipe flange is a common type of flange, widely used in the connection of medium and low pressure vessels and pipelines. Its design is simple, easy to manufacture and install, suitable for low pressure rating, pressure fluctuations, vibration and shock is not serious pipeline system.

GJQ(X)- SF double ball flexible rubber joint

GJQ (X)-SF Double Spherical Flexible Rubber Joint Diameter, Length and Displacement Parameters Table-Description: 1 Please indicate that the structural length and connection size are standard when ordering. ② If the relevant parameters of the flexible rubber joint are not within the scope of the above table, please indicate that the company can design and manufacture on its behalf.

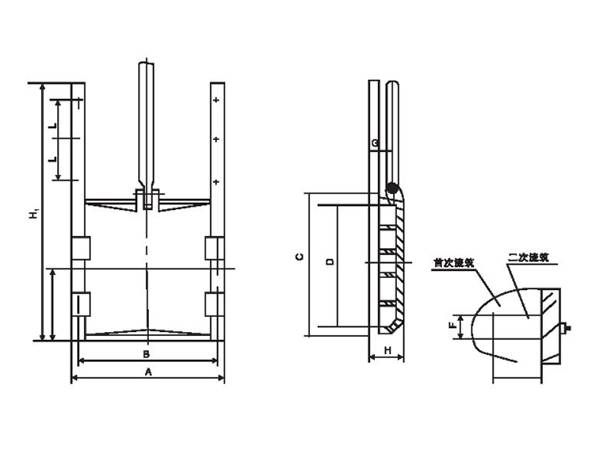

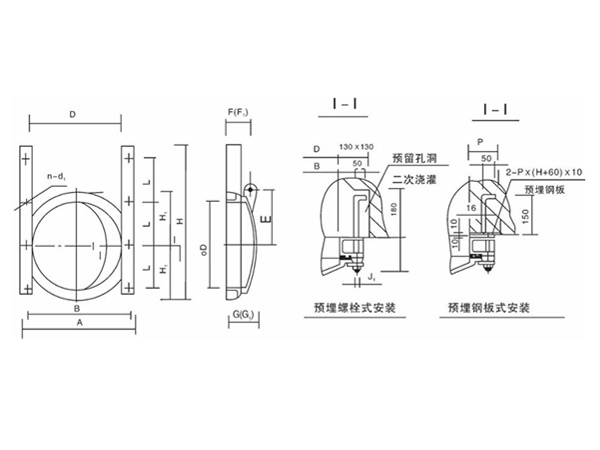

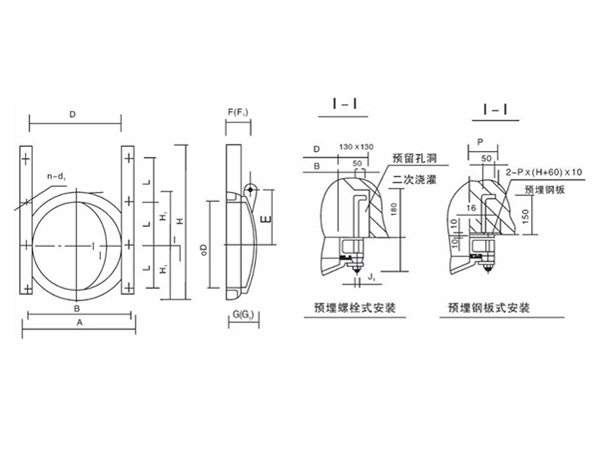

ZMQF type cast iron square gate

This product is widely used in urban water supply and drainage, metallurgy, petroleum, chemical, irrigation, electric power, textile and other industries on water treatment machine buildings to achieve flow and liquid level control, is one of the important equipment for water supply and drainage and sewage treatment.

ZMQY type cast iron circular gate

This product is widely used in urban water supply and drainage, metallurgy, petroleum, chemical, irrigation, electric power, textile and other industries on water treatment machine buildings to achieve flow and liquid level control, is one of the important equipment for water supply and drainage and sewage treatment.

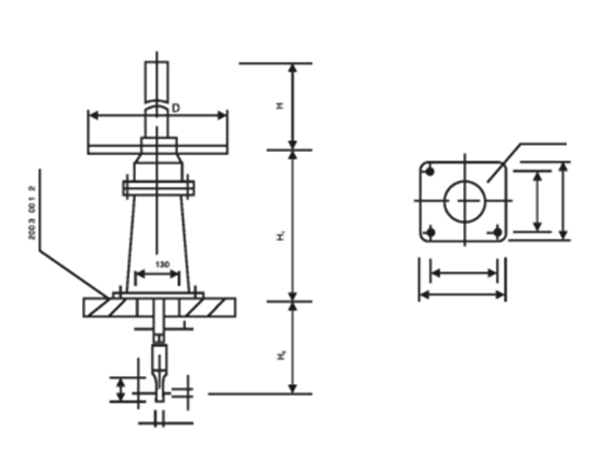

hoist

Instructions for ordering: 1. Indicate the model, caliber and whether the hoist is manual or electric; 2. Indicate the distance from the gate center to the hoist; 3. Indicate the installation form and light and dark rod; 4. Paint color and packaging requirements; 5. Please indicate if you have any special requirements. Instructions for ordering: 1. Indicate the model, caliber and whether the hoist is manual or electric; 2. Indicate the distance from the gate center to the hoist; 3. Indicate the installation form and light and dark rod; 4. Paint color and packaging requirements; 5. Please indicate if you have any special requirements.

ZMQY type cast iron circular gate

This product is widely used in urban water supply and drainage, metallurgy, petroleum, chemical, irrigation, electric power, textile and other industries on water treatment machine buildings to achieve flow and liquid level control, is one of the important equipment for water supply and drainage and sewage treatment.

Z793 Series Clamp Knife Gate Valve

This series of knife gate valve is my company design and development of a compact structure, long life, safe and reliable new knife gate valve. This series of knife-shaped gate valve is divided into two types of open gate valve and dark gate valve. In the design and manufacture, many innovative structures are adopted. The strength and stiffness of key components are checked by finite element analysis software to ensure the stable and reliable performance of this series of knife-shaped gate valves. Especially suitable for pipeline system with large amount of sediment.

Z41T Ram Wedge Gate Valve

Z41T Rod wedge gate valve is a kind of valve that relies on medium pressure to press the sealing surface of the gate plate to the sealing surface of the valve seat on the other side, thus ensuring the sealing effect. Its compact structure, reasonable design, good rigidity, unobstructed passage, and low medium resistance. Sealing surface material is usually made of stainless steel and carbide, long service life. The gate of Z41T Ram wedge gate valve can be made into a whole, called rigid gate, or it can be made into a gate that can produce trace deformation to improve manufacturability and make up for the deviation in the processing process. This gate is called elastic gate

buried gate valve

Buried gate valve is a direct buried underground valve, mainly used in urban water supply, gas and industrial pipelines and other fields. They usually have the characteristics of maintenance-free, pressure-resistant, corrosion-resistant, etc., can be used for a long time without leakage, and reduce the construction requirements of the well chamber, thereby reducing the construction difficulty and engineering cost

P747X piston type mud valve

The 100C angle pneumatic sludge discharge valve is suitable for water treatment plants to discharge sludge and wastewater in the pool. This valve is a corner-type structure, the partition will be divided into two parts of the control chamber and the flow channel, the control chamber by the diaphragm is divided into two control chamber. Seat for the flat bottom structure, sealing surface spraying ceramic, its wear resistance, corrosion resistance is very strong, and can prevent the deposition of garbage, for long-term use. The top of the valve cover and the side of the valve body are reserved with screw holes, and the pressure source enters and exits the upper and lower control chambers respectively through the control pipeline. The upper and lower chamber pressure is controlled by the solenoid valve to open or close the mud discharge valve. When the accident of sudden disappearance of the control air source occurs, the mud discharge valve can be kept closed under the inlet water pressure. (External pressure control source is air source)

PM747X diaphragm type mud discharge valve

The 100C angle pneumatic sludge discharge valve is suitable for water treatment plants to discharge sludge and wastewater in the pool. This valve is a corner-type structure, the partition will be divided into two parts of the control chamber and the flow channel, the control chamber by the diaphragm is divided into two control chamber. Seat for the flat bottom structure, sealing surface spraying ceramic, its wear resistance, corrosion resistance is very strong, and can prevent the deposition of garbage, for long-term use. The top of the valve cover and the side of the valve body are reserved with screw holes, and the pressure source enters and exits the upper and lower control chambers respectively through the control pipeline. Through the solenoid valve to control the upper and lower chamber pressure and control the mud valve to open or close, when the sudden disappearance of the control air source accident, the mud valve can be in the inlet water Press down to keep closed. (External pressure control source is air source)

200x pressure reducing valve

The product is the company's engineering and technical personnel with reference to the same type of advanced products at home and abroad to design and manufacture. The valve body adopts the whole channel streamlined design, the fluid resistance is small, the flow is large. Hydraulic operation is adopted in the rotation mode, that is, the water pressure in the pipeline is used to automatically operate the main valve flap to move up and down, control the valve port opening, adjust the downstream pressure, and maintain the downstream pressure at the pressure value set by the pilot valve spring. When the downstream pressure exceeds the set value, the pressure reducing valve will automatically close, regardless of how the inlet pressure P1 fluctuates, can output a stable outlet pressure P2. Regardless of changes in downstream flow, the outlet pressure P2 is maintained stable at the pilot valve set point. In short, the product is an ideal product for domestic water supply, fire fighting system and industrial water supply system.

AX742X Safety Pressure Relief Holding Valve

Installed in high-rise buildings, fire water supply systems and other water supply systems on the pipeline, when the pressure in the water supply pipeline exceeds the set pressure of the pressure relief valve, the pressure relief valve automatically opens for rapid pressure relief to protect the safety of the pipeline, and can also be used as a holding valve to ensure the water supply pressure upstream of the main valve. Can accurately maintain the same security set pressure, once the overpressure, the pressure relief valve quickly open, timely pressure relief. Close smooth and reliable, eliminate the pressure after-wave.

JD745X multi-function water control valve

Product overview Multi-function water control valve is installed in the high-rise building water supply system and other water supply system of the pump outlet, to prevent the media back, water hammer and water hammer phenomenon of intelligent valve. The valve has three functions of electric valve, check valve and water hammer eliminator, which can effectively improve the safety and reliability of water supply system. The technical principles of slow opening, quick closing and slow closing to eliminate water hammer are integrated. To prevent the generation of pump water hammer and stop pump water hammer. Just operate the pump motor opening and closing button, the valve can be automatically opened and closed according to the pump operating procedures, with large flow and small pressure loss. Suitable for valves below 600 caliber.

Waterproof hammer high-speed intake and exhaust valve

Waterproof hammer high-speed intake and exhaust valve is a kind of equipment used to prevent water hammer phenomenon, especially suitable for the pipeline system which is prone to sudden pressure change and impact in the water transmission pipeline. Its main functions include preventing a large amount of water from splashing, reducing the impact on the inside of the exhaust valve, extending the service life of the exhaust valve, and limitin

Metal sealed rotary ball valve

The valve is the company combined with the performance characteristics of the hard seal butterfly valve, half ball valve, ball valve, the latest development of a new structure of the valve, is currently on the market the most cost-effective type of ball valve products, after the user evaluation is very high.

Pipe force valve

Pipe valve is my company's engineering and technical personnel with reference to the same type of advanced products at home and abroad to design, in the absorption of micro-resistance slow-closing check valve, hydraulic control check valve, multi-functional water pump control valve developed on the basis of, is a new generation of water pump control valve products. It has the functions of electric gate valve, electric butterfly valve and check valve, and eliminates water hammer hazards through fast closing and slow closing actions to protect the safety of water pumps and pipe networks. The valve is a new type of pump station control equipment with novel structure, advanced performance and reliable operation. It is widely used in electric power, environmental protection, metallurgy, petroleum, petrochemical, chemical, water conservancy, municipal, food and other industries, drainage system, sewage pump room, chemical fluid and other transportation systems.

SD6 41X-10 telescopic butterfly valve

Telescopic butterfly valve is a kind of valve that uses circular butterfly plate as opening and closing parts and rotates with the valve stem to open, close and adjust the fluid channel. It is used as a component to realize the on-off and flow control of the pipeline system.

C2F double flanged force transmission joint

The double flange force transmission joint has short structure, reasonable design, reliable sealing, convenient loading and unloading, can compensate the axial displacement of the pipeline within a certain range, transmit the axial push and pull force, and has the functions of adjusting the maximum expansion amount and preventing the nozzle from loosening. It can be used instead of U-tube, bellows and other expansion joints, and is an ideal solution to the problems of pipeline installation and expansion.

ZF Cone Valve (Energy-dissipation Valve)

Cone valve is a suitable for high head, large flow conditions, no vibration, no cavitation operation, continuous discharge flow control of new valve products. Due to the use of inverted cone plunger spool named, referred to as the cone valve. Because of its excellent energy dissipation effect, it is also called energy dissipation valve. Cone valve in addition to the end of the channel is provided with a conical valve core, all the moving parts are set in the valve flow channel outside, so that the valve body internal flow is usually smooth, large flow and pressure drop loss is small, the entire working range will not produce cavitation and vibration, and in the small flow still has good flow control effect. The conical valve developed by our company has a fixed inverted conical structure. It is supported by hydraulic design and four guide wing blades used to reduce vibration. The flow rate is controlled by the front and back movement of the external movable casing. The valve body is respectively provided with metal-to-metal valve seats and supplementary soft sealing valve seats, which constitute a composite valve seat to ensure sealing performance. When discharged into the atmosphere, the water flow spreads at a wide cone angle and breaks down into a thin spray pattern, expending energy in the air. Usually according to the actual needs, can be required to control the water flow area, then install a different form of deflector at the outlet, which can not only mix the air with sufficient water, but also concentrate the flow. The results of the cone valve test showed no significant vibration, and the discharge coefficient was around 0.9 with or without the shroud when the fixed cone was fully open. ZF cone valve is mainly used in hydropower stations, reservoirs and urban water supply and drainage areas.

Heating gas fully welded fixed ball valve Q367F(H)-10/25 DN500-1200

1. Scope of application: heating system, district heating, industrial use, city gas, urban water supply. 2. Medium: water, air, oil and other fluids that do not chemically react with carbon steel. 3. Applicable temperature: Q367F type maximum applicable temperature: ≤ 200 ℃;Q367H type maximum applicable temperature: ≤ 250 ℃

worm gear drive combination valve

The worm gear combination valve is a valve control device realized by worm gear transmission technology. It is mainly used to drive the opening and closing operation of the valve to ensure that the valve can operate smoothly and accurately during the opening or closing process. Worm gear combination valve is usually composed of two parts: worm gear box and valve. The worm gear box is the key component, which is responsible for transmitting power and controlling the action of the valve.

Please Submit Your Requirements Here

0371 68197888

No. 98-1, Dengfeng Road, Shangjie District, Zhengzhou City, Henan Province

Friendly Links :

Zhengzhou valve Henan Water Conservancy Mining Machinery China Resources GasButterfly valve

Double eccentric soft seal butterfly valve

Butt welding eccentric metal seal butterfly valve

Ball valve

Heating worm gear full bore welded ball valve

Heating gas fully welded fixed ball valve

Heating gas fully welded fixed ball valve

Fitting

VSSJA-2(B2F-1) double flange limit expansion joint

C2F double flange loose sleeve force transmission joint (VSSJAF)

C2F double flange loose sleeve force transmission joint (VSSJAF)

Pressure reducing valve

YX741X adjustable pressure regulator valve

Zhengzhou Zhengvalve Machinery Co., Ltd.

Zhengzhou Zhengvalve Machinery Co., Ltd.