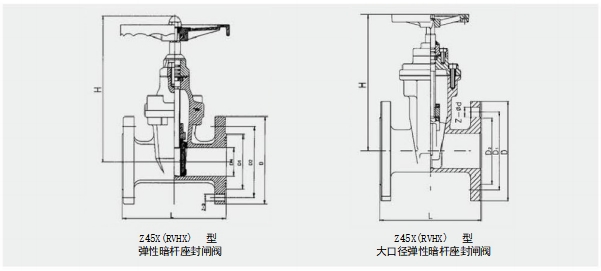

Z45X dark rod soft seal gate valve

- Product Type : Gate valve

- Introduction : For a long time, the general gate valve used in the market is generally leaking or rusting. The elastic seat seal gate valve produced by our factory imported European high-tech rubber and valve manufacturing technology overcomes the defects of general gate valve such as poor sealing, elastic fatigue, rubber aging and rust. The elastic seat seal gate valve uses the compensation effect of elastic valve to produce trace elastic deformation to achieve good sealing effect. The valve has obvious advantages such as light opening, reliable sealing, good elastic memory and long service life, it can be widely used in tap water, sewage, construction, petroleum, chemical industry, instrument, medicine, textile, electric power, ship, metallurgy, energy system and other fluid pipelines as regulating and intercepting devices.

Product Details

Overview

For a long time, the general gate valve used in the market is generally leaking or rusting. The elastic seat seal gate valve produced by our factory imported European high-tech rubber and valve manufacturing technology overcomes the defects of general gate valve such as poor sealing, elastic fatigue, rubber aging and rust. The elastic seat seal gate valve uses the compensation effect of elastic valve to produce trace elastic deformation to achieve good sealing effect. The valve has obvious advantages such as light opening, reliable sealing, good elastic memory and long service life, it can be widely used in tap water, sewage, construction, petroleum, chemical industry, instrument, medicine, textile, electric power, ship, metallurgy, energy system and other fluid pipelines as regulating and intercepting devices.

Features

· Flat Bottom Seat:

The traditional gate valve is often in the water washing pipe after the foreign objects such as stones, wood, cement, paper scraps, debris and other silting in the groove at the bottom of the valve, easy to cause can not be closed tightly and the formation of water leakage phenomenon. The bottom of the soft sealing gate valve adopts the same flat bottom design as the water pipe, which is not easy to cause debris deposition and make the fluid unobstructed.

· Overall encapsulation:

The valve plate adopts high quality rubber for integral inner and outer packing. The domestic first-class rubber vulcanization technology enables the vulcanized valve plate to ensure accurate geometric dimensions, and the rubber and ductile iron gate are firmly connected, not easy to fall off and have good elastic memory.

· Corrosion resistance:

The valve body is coated with epoxy resin at high temperature, which can prevent corrosion and rust of the valve body and can be used in sewage system.

· Not easily broken:

In the past, the traditional cast iron gate valve is often hit by foreign objects, collision or overlap caused by fracture and other phenomena. Due to the valve switch to ductile iron, this situation has been greatly reduced.

Three "O" ring seal:

Because the valve stem adopts three "0" ring sealing ring seal design, it can reduce the friction resistance when switching, and greatly reduce the water leakage phenomenon. The sealing ring can be replaced without stopping water construction.

· Helps to drink:

Since the valve body is coated with non-toxic epoxy resin, the inner and outer surfaces of the gate are completely covered with rubber without rust or corrosion, which is available for raw drinking.

· Precision cast valve body:

The valve body adopts precision casting, and the precise geometric dimensions make the valve body inside without any finishing to ensure the sealing of the valve.

· Light weight:

The valve is made of ductile ink casting, the weight of the traditional gate valve weight reduction of about 20%-30%. Easy installation and maintenance.

Outline connection dimension (mm)

|

公称直径 |

L:结构长度 |

D:法兰外径 |

D1:密封面直径 |

D2:螺栓孔 中心圆直径 |

Z-D:孔数和孔径 |

H:高度 |

|||||

|

1.0Mpa 1.6Mpa |

1.0Mpa 1.6Mpa |

1.0Mpa 1.6Mpa |

1.0Mpa 1.6Mpa |

.0Mpa 1.6Mpa |

1.0Mpa 1.6Mpa |

||||||

|

DN50 |

178 |

165 |

99 |

125 |

4-φ19 |

245 |

|||||

|

DN65 |

190 |

185 |

118 |

145 |

4-φ19 |

270 |

|||||

|

DN80 |

203 |

200 |

132 |

160 |

4-φ19 |

8-φ19 |

300 |

||||

|

DN100 |

229 |

220 |

156 |

180 |

8-φ19 |

320 |

|||||

|

DN125 |

254 |

250 |

184 |

210 |

8-φ19 |

365 |

|||||

|

DN150 |

267 |

285 |

211 |

240 |

8-φ23 |

420 |

|||||

|

DN200 |

292 |

340 |

266 |

295 |

8-φ23 |

12-φ23 |

540 |

||||

|

DN250 |

330 |

395 |

405 |

319 |

350 |

355 |

12-φ23 |

12-φ28 |

670 |

675 |

|

|

DN300 |

356 |

445 |

460 |

370 |

400 |

410 |

12-φ23 |

12-φ28 |

695 |

700 |

|

|

DN350 |

381 |

505 |

520 |

429 |

460 |

470 |

16-φ23 |

16-φ28 |

805 |

810 |

|

|

DN400 |

406 |

565 |

580 |

480 |

515 |

525 |

16-φ28 |

16-中31 |

845 |

850 |

|

|

DN450 |

432 |

615 |

640 |

530 |

548 |

565 |

585 |

20-φ28 |

20-φ31 |

1002 |

1025 |

|

DN500 |

457 |

670 |

715 |

582 |

609 |

620 |

650 |

20-φ28 |

20-φ34 |

1120 |

1150 |

|

DN600 |

508 |

780 |

840 |

682 |

720 |

725 |

770 |

20-φ31 |

20-φ37 |

1270 |

1300 |

|

DN700 |

610 |

895 |

910 |

794 |

794 |

840 |

840 |

24-φ31 |

24-φ37 |

1540 |

1550 |

|

DN800 |

660 |

1015 |

1025 |

901 |

901 |

950 |

950 |

24-φ34 |

24-φ40 |

1745 |

1750 |

|

DN900 |

711 |

1115 |

1125 |

1050 |

1050 |

1001 |

1001 |

28-φ34 |

28-φ40 |

1782 |

1782 |

|

DN1000 |

811 |

1230 |

1255 |

1160 |

1170 |

1112 |

1112 |

28-φ37 |

28-中43 |

1835 |

1835 |